All Categories

Featured

Table of Contents

- – Rv Interior Remodel Chino Hills, CA

- – OCRV Center

- – Rv Couch Chino Hills, CA

- – Rv Carpet Replacement Chino Hills, CA

- – Replacement Windows For Campers Chino Hills, CA

- – Replacement Rv Refrigerator Chino Hills, CA

- – Rv Interior Remodel Chino Hills, CA

- – Rv Dining Table Chino Hills, CA

- – Remodeling Rv Chino Hills, CA

- – Replace Rv Flooring Chino Hills, CA

- – Rv Carpet Replacement Chino Hills, CA

- – Rv Dining Table Chino Hills, CA

- – OCRV Center

Rv Interior Remodel Chino Hills, CA

Just like the home windows in your automobile or home, there are a few various kinds. Possibly you desire a home window in your door to ensure that you can allow the sunlight? Examine! The Motor Home Entry Door Obscure Glass Window is ideal for that, with the addition that you can have your privacy while still allowing the light.

And if you want your windows to be tinted, we can help you there. I'm certain you're conscious of all that a home window can do.

Without the windows to allow in the light to inform you whether it's night or day, you might get all kinds of blended, perhaps even miss out on a large event. Or visualize you're having a cookout with your household and you run inside to get some even more hot canines. Without a home window, you wouldn't be able to see that your daughter is obtaining extremely near the fire and no person else has discovered yet.

Rv Couch Chino Hills, CA

The sun is a terrific decorating tool to make use of, lighting up space and visually broadening it. All the most effective decorators know just how much of an effect illumination can have. Whether you're using it to draw focus to an impressive piece of artwork or add heat to an entire space, illumination makes all the distinction in a room.

If you have older windows that require changing, the procedure for mounting the new home windows isn't as very easy as it looks. You need to get rid of the internal framework of the old window by getting rid of the screws. You require to remove the external structure of the home window by pushing it out of the home window location.

Next off, eliminate any of the old sealants from the location with a putty blade. Once that is done, tidy the location with an appropriate cleanser. When your location is tidy and free of particles, inspect the architectural components of the window opening. If there is anything that needs repaired (rusted staples, for instance), make certain you repair them before mounting the new home window.

Again, see to it you are making use of the aid of another individual to maintain whatever straight and even and stop the window from dropping. As soon as the external structure and the glass structure are in location, protect them by placing and securing the inner framework on the within the window area.

Rv Carpet Replacement Chino Hills, CA

Our company believe in providing the greatest value, quality, and selection (Chino Hills Rv Replacement Awnings). Plus, we desire you to enjoy your purchase! In case you wish to send out a product back to us, you might return most extra things for a reimbursement or exchange, minus delivery, within 90 days from the day of purchase unless kept in mind listed below under exemptions and exclusions

A return permission will be supplied, and, in every case, we'll start to maintain an eye out for your return. For web orders returned in-store, please take the thing in initial product packaging, along with the invoice to any kind of Camping World retail locations for a refund or exchange.

Replacement Windows For Campers Chino Hills, CA

Refunds for internet orders released in-store are able to be reimbursed to a PRESENT CARD or SENT BY MAIL CHECK ONLY; some exemptions might use. For retail acquisitions returned with a receipt, please return the unused and unopened item, with the initial sales receipt, for a complete refund or exchange. All returns with a present invoice will get a shop credit score for the quantity of the product at the time of acquisition.

When it comes to Recreational vehicle travel, having the appropriate windows can make all the difference. Whether you're looking for much better insulation, enhanced air flow, or simply a far better view, there are a couple of vital factors to take into consideration when selecting the finest Motor home window for your automobile. Here are five suggestions to help you make an informed choice and appreciate your journeys to the max.

Replacement Rv Refrigerator Chino Hills, CA

Fixed windows are fixed and can not be opened up, while gliding home windows can be opened horizontally or vertically. Awning home windows are pivoted at the top and open outward, offering superb air flow. Consider the type of home window that will best suit your requirements and preferences prior to buying. When choosing a motor home window, it is necessary to search for premium materials and building and construction.

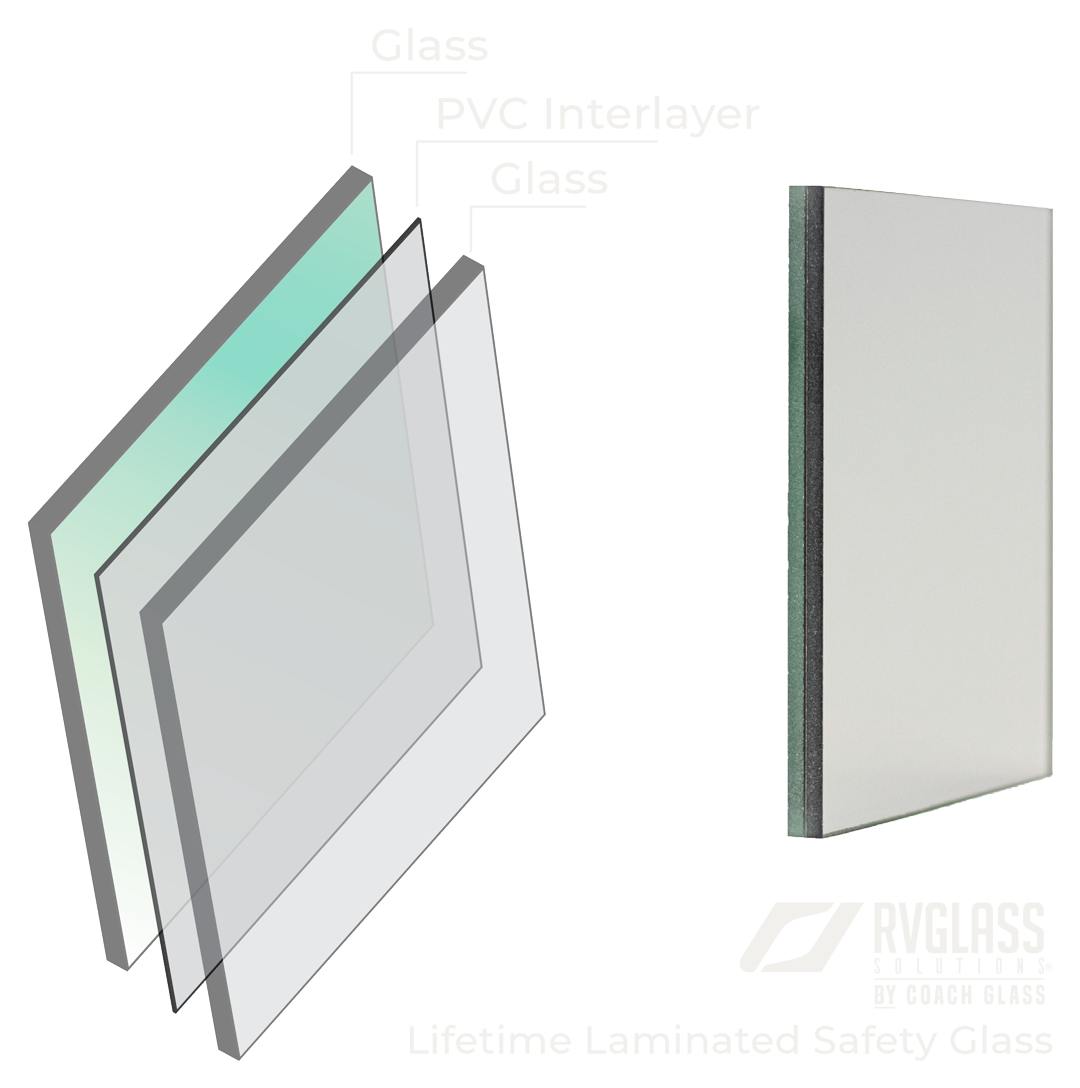

Search for windows that are made from solidified glass, which is stronger and extra immune to breakage than routine glass. Furthermore, the framework needs to be made from durable products like light weight aluminum or plastic, and must be developed to stop leaks and drafts. Spending in a premium motor home home window will certainly make sure that it lasts for years and supplies reputable efficiency on your trips.

The home window needs to fit snugly right into the area provided, with no voids or areas that could enable drafts or leakages. Measure the opening meticulously and pick a home window that matches the dimensions. Furthermore, take into consideration the form of the home window and just how it will certainly fit with the total layout of your motor home.

Rv Interior Remodel Chino Hills, CA

Your recreational vehicle's home windows are the key to satisfying camping, letting you see all the sights of the road and your locations. If you're driving a motorhome, the windscreen is the most essential home window on the entire recreational vehicle. Despite which kind of recreational vehicle you have, your home windows are a vital part of camping.

Older RVs were developed with less advanced home window systems, so there is wear and tear that might be noticeable., however certain issues like haze, scrapes, or problems with the covering of the window may indicate it's time to change your Recreational vehicle home windows.

There are splits, deep scratches, or chips in the windows. The windows are no more firmly secured. Wind or water goes into the gear from around the home windows, also when the windows are shut. Your windows aren't effectively protected. Your home windows rattle when the recreational vehicle is in activity. Wondering if it's time for a motor home home window replacement? Call your local Lazydays recreational vehicle car dealership for more information concerning our window replacement and motor home glass repair service solutions! When changing your RV home windows, you have the ability to choose the right window for your RV and your demands.

Rv Dining Table Chino Hills, CA

There are additionally alternatives such as clear glass, pebbled windows, and colored motor home windows. Your design, safety and security, and window utilize requirements will certainly aid determine which type of motor home home window you select. Your motor home's window structures combine the exterior and interior aspects of your motor home, and they need to be properly set up to ensure that the sidewall's seal stays water tight.

The most effective means to see to it that your recreational vehicle window replacements are mounted effectively is to leave it to the experts. Our recreational vehicle solution specialists can replace any kind of home windows and glass on your recreational vehicle, consisting of the windshield, side windows, and also the much more intricate RV door home window replacement. Door windows, otherwise set up effectively, can rattle when you're utilizing the RV door, so leave that fixing to our experts at Lazydays recreational vehicle.

Remodeling Rv Chino Hills, CA

These home windows open outside with a crank system, permitting air flow while minimizing rainfall entry (Chino Hills Rv Replacement Awnings). Commonly larger windows that do not open, giving unobstructed sights and light if furnished. Prior to we dive right into the procedure of RV home windows, it's essential to understand how they are installed. Right here's a brief introduction of the parts associated with a common home window installation: The primary glass unit.

Fasteners protecting the keeping ring. Gives a watertight seal around the window. These elements are mounted on the manufacturing line soon after the wall assembly, ensuring the architectural honesty of your RV. While RV windows vary from household home windows, they require regular attention and maintenance to prevent problems like water leaks.

Replace Rv Flooring Chino Hills, CA

To guarantee the durability and performance of your RV windows, take into consideration the complying with pointers: Take a look at the location where the window meets the wall surface for any kind of spaces or voids. In extreme instances, you might require to get rid of the home window and reinstall it utilizing putty or foam seal.

We encourage customers to validate the contents and seek advice from their dealership or Keystone RV for the most current details. If you have any inquiries or need additional clarification, please do not be reluctant to contact your dealer or connect to Keystone recreational vehicle directly.

These are the devices we needed for our camper home window substitute. Depending on your RV, you might or might not need all of these devices for your job.

No matter where you acquire your brand-new RV window, you'll need to supply exact dimensions. Let's damage down our process for gauging a motor home home window for replacement. Begin by getting rid of any window valance, blinds, or shades. Next, get rid of all screws around the border of the home window, and remove the inside framework.

Rv Carpet Replacement Chino Hills, CA

Don't place any external stress on the window while taking your dimensions, or it could come loosened and loss. For added safety, you might intend to have a helper on a ladder outside, holding the window in area while you determine. Carefully eliminate the frame of your old home window so that you can measure the opening (NOT the home window itself).

For our rectangle-shaped home window, we required to take just 4 dimensions. Be mindful that we're measuring the opening itself. Using a gauging tape, take mindful note of the width and height of the opening. It's a great idea to take dimensions at a number of factors so you have a concept of how easily the home window opening was reduced.

Rv Dining Table Chino Hills, CA

Next, gauge the density of the wall (deepness of the window), from the exterior wall surface to the indoor wall surface. For this measurement, utilize your leader (with dimensions that run right throughout). Put the leader into the wall up until it touches the beyond the home window structure.

Dimensions of the old home window and the home window opening are frequently various. In reality, they can vary as long as half an inch on the sides, top, and base. Window producers utilize filler strips to keep the home window level and snug. This is why it's so essential to gauge the opening and not the original home window itself.

Procedure two times, cut as soon as? Take your time to obtain an exact measurement, and verify it by determining a 2nd time. Precise measurements are vital to motor home home window replacement. You do not wish to loosely determine and round up or down. Constantly gauge to the closest 1/16th of an inch. Take a close consider your tape measure and make certain you understand which are the 1/16th-inch dimensions.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

The home window makers are the most effective authorities on mounting their items. The supplier of your new motor home home window has likely included valuable standards or pointers to make the installment easier. These kinds of directions are usually included on producers' internet sites too. If your new home window included instructions in the plan, make certain to maintain those convenient, as they may have described step-by-step instructions in a consisted of pamphlet.

Rv Sofas Chino Hills, CARv Chairs Chino Hills, CA

Rv Sofas Chino Hills, CA

Rv Couch Bed Chino Hills, CA

Awnings For Trailers Chino Hills, CA

Replacement Rv Refrigerator Chino Hills, CA

Rv Sofa Beds Chino Hills, CA

Replacement Windows For Campers Chino Hills, CA

Rv Interior Furniture Chino Hills, CA

Remodeling Rv Chino Hills, CA

Rv Dinette Booth Chino Hills, CA

Motorhome Carpets Chino Hills, CA

Rv Replacement Furniture Chino Hills, CA

Rv Replacement Furniture Chino Hills, CA

Rv Upholstery Chino Hills, CA

Rv Couch Bed Chino Hills, CA

Rv Refrigerator Replacement Chino Hills, CA

Rv Interior Remodel Chino Hills, CA

Motorhome Carpets Chino Hills, CA

Rv Restoration Companies Chino Hills, CA

Rv Carpet Replacement Chino Hills, CA

Awnings For Rv Chino Hills, CA

Rv Couch Chino Hills, CA

Rv Replacement Awnings Chino Hills, CA

Rv Replacement Awnings Chino Hills, CA

Rv Couch Chino Hills, CA

Rv Sofas Chino Hills, CA

Replacement Rv Windows Chino Hills, CA

Rv Upholstery Chino Hills, CA

Awnings For Rv Chino Hills, CA

Rv Interior Furniture Chino Hills, CA

Rv Dinette Table Chino Hills, CA

Rv Dinette Table Chino Hills, CA

Rv Replacement Furniture Chino Hills, CA

Awnings For Rv Chino Hills, CA

Rv Sofa Sleeper Chino Hills, CA

Replacement Windows For Rv Chino Hills, CA

Replacement Windows For Campers Chino Hills, CA

Rv Dining Table Chino Hills, CA

Rv Interior Furniture Chino Hills, CA

Replacement Windows For Rv Chino Hills, CA

Rv Restoration Companies Chino Hills, CA

Rv Dinette Booth Chino Hills, CA

Rv Carpet Installation Chino Hills, CA

Rv Couch Bed Chino Hills, CA

Rv Replacement Furniture Chino Hills, CA

Awnings For Rv Chino Hills, CA

Rv Dinette Table Chino Hills, CA

Replace Rv Flooring Chino Hills, CA

Rv Restoration Companies Chino Hills, CA

Rv Interior Furniture Chino Hills, CA

Replacement Windows For Rv Chino Hills, CA

Rv Sofa Beds Chino Hills, CA

Awnings For Trailers Chino Hills, CA

Rv Carpet Installation Chino Hills, CA

Rv Sofas Chino Hills, CA

Rv Interior Furniture Chino Hills, CA

Replace Rv Flooring Chino Hills, CA

Rv Carpet Replacement Chino Hills, CA

Rv Replacement Awnings Chino Hills, CA

Remodeling Rv Chino Hills, CA

Rv Sofa Beds Chino Hills, CA

Rv Dining Table Chino Hills, CA

Rv Upholstery Chino Hills, CA

Rv Sofa Sleeper Chino Hills, CA

Rv Replacement Awnings Chino Hills, CA

Replacement Windows For Campers Chino Hills, CA

Rv Interior Remodel Chino Hills, CA

Replace Rv Flooring Chino Hills, CA

Rv Interior Remodel Chino Hills, CA

Rv Sofa Sleeper Chino Hills, CA

Rv Replacement Awnings Chino Hills, CA

Rv Replacement Furniture Chino Hills, CA

Rv Couch Bed Chino Hills, CA

Rv Refrigerator Replacement Chino Hills, CA

Rv Carpet Installation Chino Hills, CA

Rv Upholstery Chino Hills, CA

Replacement Rv Windows Chino Hills, CA

Find A Seo Optimization Chino Hills, CA

Close To Me Seo Citations Chino Hills, CA

OCRV Center

Table of Contents

- – Rv Interior Remodel Chino Hills, CA

- – OCRV Center

- – Rv Couch Chino Hills, CA

- – Rv Carpet Replacement Chino Hills, CA

- – Replacement Windows For Campers Chino Hills, CA

- – Replacement Rv Refrigerator Chino Hills, CA

- – Rv Interior Remodel Chino Hills, CA

- – Rv Dining Table Chino Hills, CA

- – Remodeling Rv Chino Hills, CA

- – Replace Rv Flooring Chino Hills, CA

- – Rv Carpet Replacement Chino Hills, CA

- – Rv Dining Table Chino Hills, CA

- – OCRV Center

Latest Posts

Professional Family Photos Garden Grove

Graduation Photographers Near Me Villa Park

San Leandro Stone Patio Contractor

More

Latest Posts

Professional Family Photos Garden Grove

Graduation Photographers Near Me Villa Park

San Leandro Stone Patio Contractor